Capability & Capacity

With a wide range of capabilities and the capacity to match, we are able to meet the demands of the global energy, oil and petrochemical industries, whilst ensuring the manufacture of high quality and fully traceable high integrity bolting.

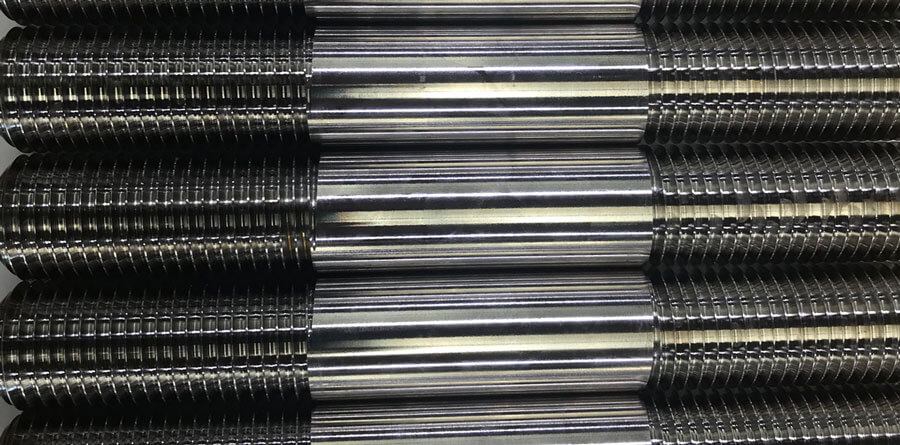

Threaded Components

Our thread-rolling manufacturing capability allows us to roll components up to 7” diameter including internal die manufacture. In addition, all products are available with a wide variety of resistant finishes to prevent corrosion.

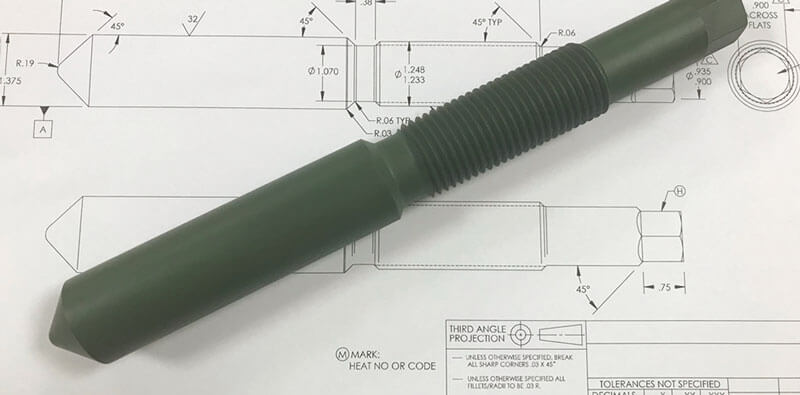

Specialist Machined Components

Using our state-of-the-art manufacturing facility, we can deliver bespoke specialised machined components to customers’ requirements and drawings.

Material Grades

With a full material range, we are able to meet the requirements for our customers in a variety of industries. Our material ranges include: A453 660, 718, Inconel, Durehete, Nimonics™, AISI 4340.

ASTM and ASME standards

All material grades available are released to both ASTM and ASME Standards. This ensures all materials and manufactured to the industry standards and the quality of the components has not been compromised.

Machining Capability

At Beck Prosper, we have 20 CNC lathes and two new Doosan Puma turning lathes. This also incorporates machining centres, presses, wire erosion and 8 manual lathes.

Riser Bolt Manufacture

Riser bolts are special high integrity bolting with demanding metallurgical and physical properties. We are one of the few suppliers able to manufacture the components out of materials such as AISI 4340.

Plating and Coating

We offer a wide range of platings and coatings for high integrity bolting to ensure your components are durable and protected from corrosion.

This includes heat treatment and testing, shot blasting, PTFE (anti-corrosion coatings), Hot Dip Galvanising, Phosphate, Molykote, Zinc Nickel, and Zinc Plating.

Stock

With more than 3,000 tonnes of raw materials and finished products held in stock, we can deliver components at unbeatable lead times. We also work in partnership with our clients to maintain an inventory of customer specific parts to enhance our service to them.

Accredited Laboratory

The on-site ISO 17025 independently accredited Laboratory is equipped with the very best testing equipment and inspection procedures. All products are rigorously scrutinised prior to dispatch to ensure quality standards are met and well documented. Third party inspection can be arranged with any of the leading agencies including Lloyds, TUV and DNV.

Want more information?

Simply fill out our form, call

+44 (0) 1384 368 888, or click here to get in touch via email.